Context

Castrol, a subsidiary of the BP group and a specialist in industrial lubricants, operates a factory in Péronne. As part of strengthening its safety standards, Castrol launched a pilot project at these facilities.

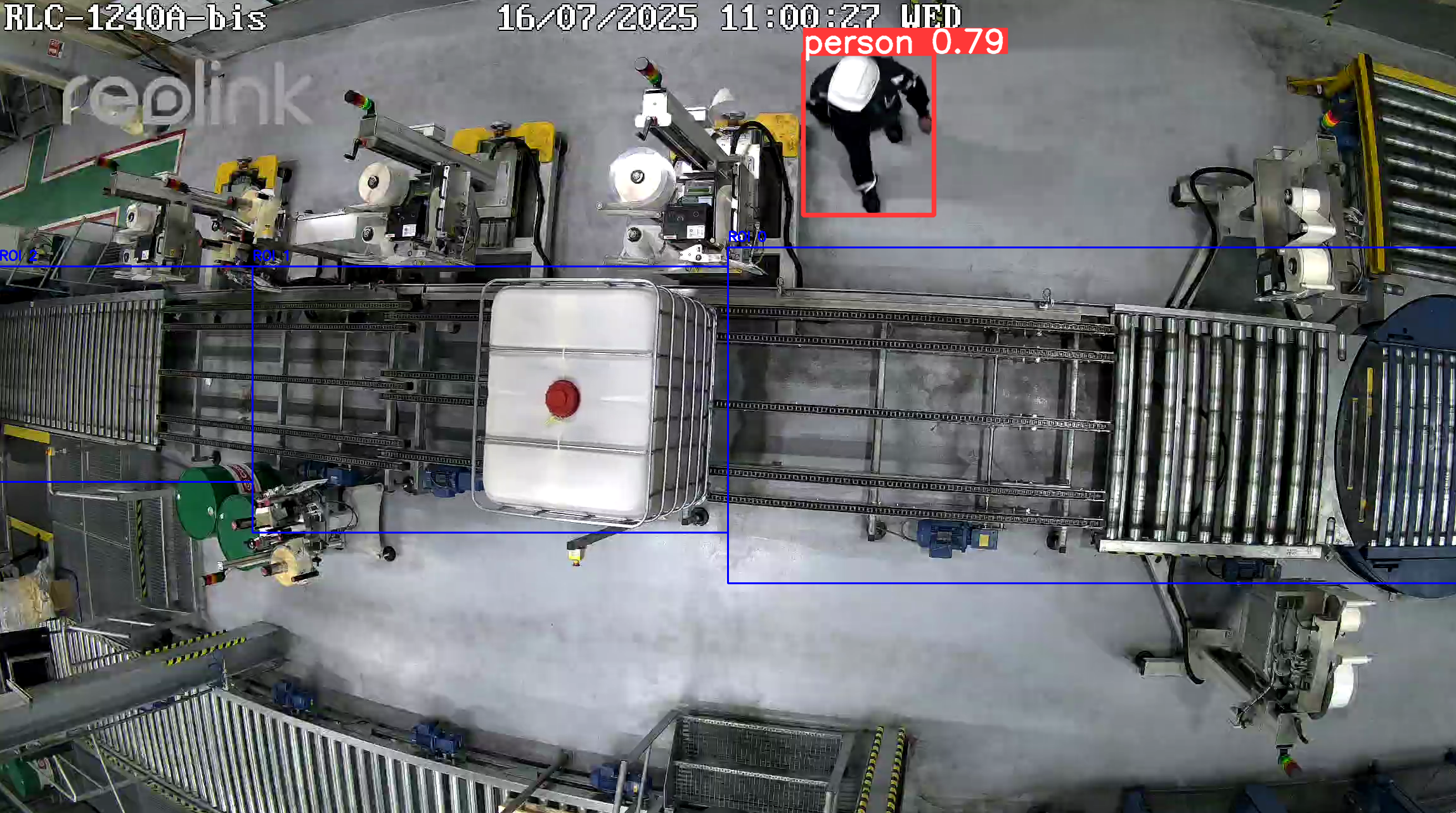

The objective was to implement a computer vision system to monitor a packaging line (barrel filling) and detect any human intrusion in real time.

This project addressed two main challenges:

Operator safety:

ensuring the protection of teams working near the automated line.

Regulatory compliance:

following a quality audit that highlighted a safety gap, Castrol needed to deploy an effective alerting solution to meet the Group’s requirements.

The solution: on‑premises, bespoke detection

To meet Castrol’s needs, Galadrim developed a complete solution combining hardware and software.

Training a computer vision model

We trained a YOLO (You Only Look Once) object‑detection model, specialised in detecting people and their postures. To ensure reliability, the model was trained with a dataset created specifically for the project:

Hardware deployment

The hardware solution includes an NVIDIA GPU to run the detection model, as well as a control screen so operators can view alerts instantly.

Challenges overcome

Implementing this solution meant overcoming several technical and environmental constraints specific to the factory.

No Internet connectivity

The packaging line had no Internet access. It was therefore essential to design a self‑contained system. We addressed this by using a dedicated NVIDIA GPU capable of running the computer vision model entirely locally, without relying on the cloud.

Physical installation

Camera positioning was critical to ensure complete visual coverage of the line. After a site visit, our teams advised Castrol’s staff on installing a custom support system, positioned above the line so the cameras could be fixed in the optimal location.

Hardware configuration

The project involved significant hardware engineering, notably the advanced configuration of NVIDIA cards to optimise real‑time detection.